BQCIS — Agriculture & ForestryIndependent inspection and assurance across crops, forestry, and agricultural supply chains |

The agriculture and forestry sectors are critical to global food security, renewable resources, and sustainable trade. From grain silos and cold storage facilities to timber yards and plantation management, every stage demands impartial verification. BQCIS provides independent inspection, testing, and certification services to help producers, exporters, traders, and regulators meet international standards and safeguard product integrity.

Quick Navigation

- Why BQCIS? (Core Value Proposition)

- Who We Serve (Sector Coverage)

- Our Services (Functional Breakdown)

- Compliance & Standards (Global Alignment)

- How We Work (Step-by-Step)

- Deliverables (“What You Get”)

- Service Levels & SLA

- Risk & Dispute Management

- Digital Assurance & Client Portal

- Case Studies & Applications

- Core Agriculture Coverage

- Forestry & Timber Traceability

- Agri-Food Safety & Perishables

- Sustainability & Certification

- Logistics & Cold Chain Oversight

- Call to Action (Conversion Goal)

Greenhouse Crop Inspection – Growth Monitoring, Pest Control, and GAP Compliance

Inspection Checklist

Why BQCIS Agriculture

BQCIS provides impartial oversight from farm to export terminal, aligned with GAFTA, FOSFA, Codex, and ISO standards for defensible trade. Read More →

Why BQCIS? (Core Value Proposition)

BQCIS provides independent agricultural and forestry assurance aligned with the world’s most recognized trade, safety, and sustainability frameworks. Our impartial inspections reduce disputes, accelerate clearances, and provide arbitration-ready evidence for global stakeholders.

- Independent Oversight — Trusted by GAFTA, FOSFA & Codex trade rules.

- Accredited Testing — ISO 17025 labs and globally aligned protocols.

- QR-Secure Certification — Recognized by CIQ (China), USDA, EU.

- Faster Clearance — Prevent rejections at CIQ, EU, and GCC ports.

- Trade Dispute Defense — Evidence packs that hold up in GAFTA arbitration.

- Sustainability Leadership — Support for ESG, EUDR, and biodiversity compliance.

These core values position BQCIS as the trusted partner for agricultural, forestry, and food supply chain assurance worldwide. Read More →

Grain Quality & Field Sampling Inspection

Sampling Tools

Assurance Value

Field-level sampling ensures accurate grading and defensible results for trade settlements. Read More →

Who We Serve (Sector Coverage)

BQCIS provides impartial assurance across the agricultural and forestry supply chain, serving stakeholders from farm-level production to global finance. Each inspection program is aligned with GAFTA, FOSFA, Codex, and ISO frameworks for defensible compliance.

- Growers & Cooperatives — Farm-level quality and sustainability assurance.

- Exporters & Traders — Defensible sampling and certification under GAFTA/FOSFA.

- Processors & Packers — Verified compliance with HACCP & ISO 22000.

- Retailers & Importers — Traceability and consumer safety assurance.

- Commodity Exchanges — Standardized certification for listings.

- Insurers & Banks — Neutral verification that reduces risk exposure.

With BQCIS, every stakeholder benefits from transparency, reliability, and arbitration-ready evidence. Read More →

Greenhouse Crop Inspection & Cultivation Monitoring

Stakeholder Groups

Value Delivered

Independent verification ensures trust across the supply chain, from farm to global markets. Read More →

Compliance & Standards (Global Alignment)

BQCIS ensures agricultural and forestry supply chains align with international regulations, protecting clients from rejections, trade disputes, and compliance gaps.

| Regulatory Body | Standard | Focus Area |

|---|---|---|

| GAFTA / FOSFA | 124, 130 | Sampling & Trade Dispute |

| Codex Alimentarius | CAC/RCP | Food Safety & Residues |

| ISO | 17025, 22000, 9001 | Labs, HACCP, Quality Systems |

| EU EFSA / CIQ / USDA FSIS | EC 396/2005, FSMA | Market Access Compliance |

| EU EUDR | Due Diligence Req. | Deforestation-Free Supply Chains |

Every inspection is backed by global standards, ensuring defensibility across audits, certifications, and international trade. Read More →

Egg Quality & Grading Inspection

Key Regulatory Bodies

Why Standards Matter

Alignment with international standards ensures defensible certification, prevents rejections, and protects clients in global trade. Read More →

How We Work: Plan → Sample → Test → Verify → Certify

BQCIS follows a transparent, step-by-step methodology that ensures every agricultural and forestry inspection is defensible, traceable, and globally recognized. Our structured approach minimizes disputes, accelerates clearances, and provides clients with QR-secured documentation.

- Plan — Scope aligned with trade rules & buyer specifications.

- Sample — Representative sampling under ISO/GAFTA protocols.

- Test — ISO 17025-accredited laboratories and validated methods.

- Verify — Compliance checks against regulatory and buyer thresholds.

- Certify — QR-secure certificates accepted by regulators, buyers & banks.

Each step is documented with digital records and evidence packs, ensuring accountability across the entire inspection process. Read More →

Timber & Lumber Grading Inspection

Phytosanitary Focus

Assurance Value

Timber inspections ensure compliance with export requirements, prevent pest contamination, and safeguard clients against costly trade disputes. Read More →

Deliverables — What You Get

Every BQCIS agricultural or forestry inspection culminates in a defensible evidence package. These deliverables provide regulators, buyers, and financial institutions with traceable proof of compliance, protecting stakeholders in global trade.

- Sampling Plan — Farm-to-port representative sample strategy.

- Grading Sheets — Commodity-specific grading aligned with GAFTA/FOSFA.

- Laboratory Certificates — ISO 17025 verified test results.

- Seal/Tally Logs — Custody seals and chain-of-custody records.

- CAPA Reports — Corrective and Preventive Action reporting.

- QR-Secure Certificates — Digitally authenticated, arbitration-ready.

All deliverables are securely archived in the BQCIS Client Portal for long-term access and verification.

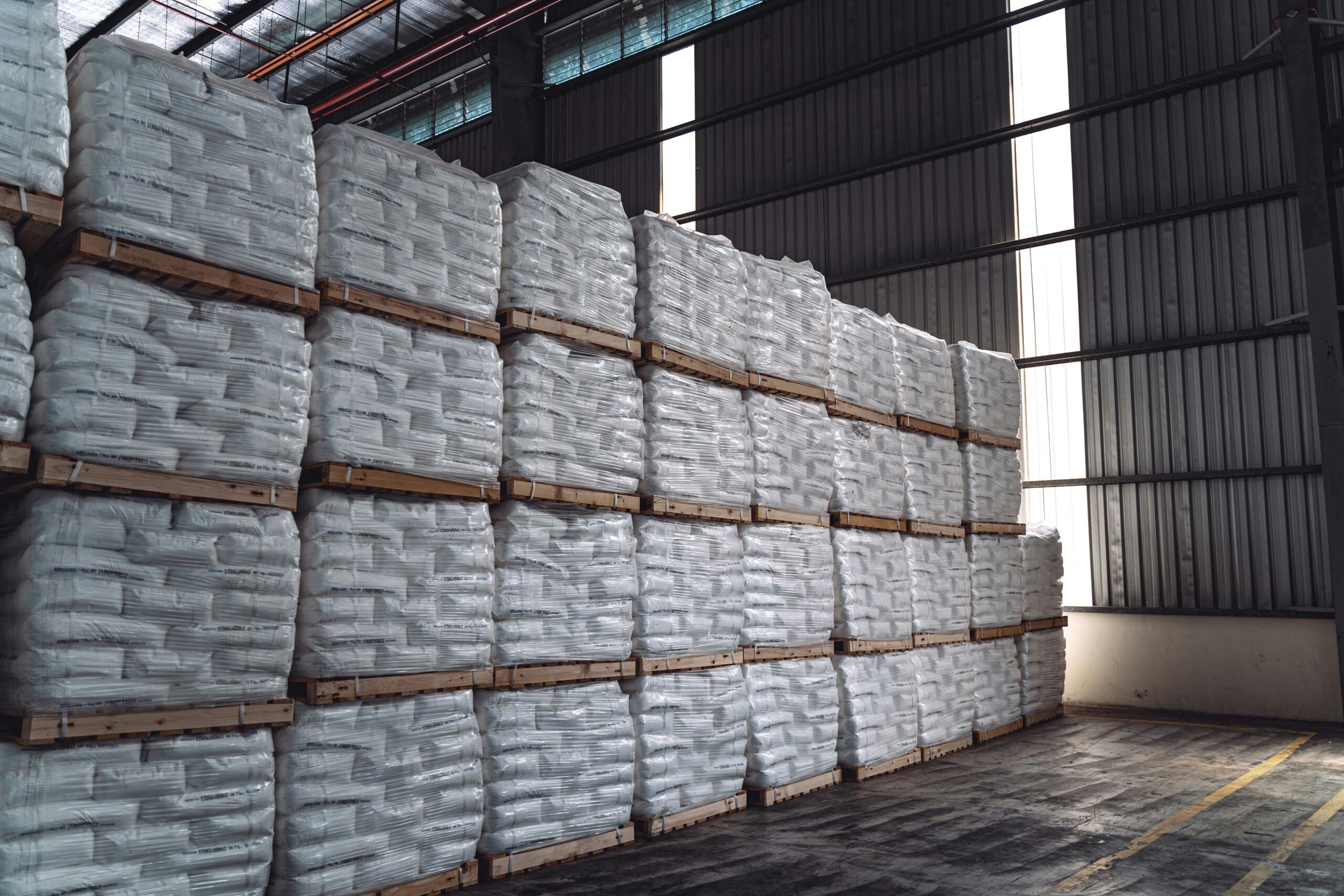

Agricultural Bulk Bag Storage & Handling Inspection

Deliverable Types

Assurance Value

Deliverables provide evidence for regulators, buyers, and banks — ensuring defensible trade, compliance with GAFTA/FOSFA, and seamless customs clearance. Read More →

Service Levels & SLA

BQCIS structures its agricultural and forestry inspections into tiered service levels. Each SLA (Service Level Agreement) ensures predictable timelines, defensible results, and scalability to meet the needs of exporters, growers, and commodity traders.

| Level | Target Use Case | Turnaround |

|---|---|---|

| Express | Perishables (fruits, vegetables, seafood). | 24–48 hours. |

| Standard | Grains, pulses, processed foods. | 3–5 days. |

| Complex | Multi-site/export programs, arbitration-sensitive shipments. | 7–10 days. |

KPIs tracked include volume variance, reporting timeliness, resample rates, and retained sample integrity.

Soybean Sampling & Quality Verification

Turnaround Options

Why SLAs Matter

Service tiers align with commodity perishability and trade urgency, reducing risk of rejection at ports and accelerating clearances. Read More →

Risk & Dispute Management

Disputes in agricultural trade often arise from quality, weight, or compliance variances. BQCIS provides structured risk management and defensible protocols that help resolve conflicts at inspection, arbitration, or regulatory levels.

- Triggers — MRL failures, GAFTA/FOSFA grading disputes, and CIQ rejections.

- Retained Samples — Custody-sealed per GAFTA/FOSFA protocols.

- Umpire Testing — Neutral ISO 17025 laboratories for arbitration.

- Reconciliation Reports — Evidence packs submitted to trade panels.

These services safeguard clients in arbitration (GAFTA/FOSFA), market access (CIQ/USDA), and regulatory enforcement, ensuring disputes are resolved quickly and fairly. Read More →

Rice Quality & Export Grading Inspection

Dispute Triggers

- MRL failures (residues, contaminants).

- GAFTA/FOSFA grading disputes.

- CIQ/EU port rejections.

Resolution Tools

Retained samples and umpire lab testing ensure defensible outcomes during arbitration or trade disputes. Read More →

Digital Assurance & Client Portal

BQCIS connects agricultural and forestry inspections directly to clients through our Digital Assurance Hub. Each inspection produces a secure QR-referenced record that can be verified by buyers, regulators, and banks in real time.

- QR Verification — Accepted by CIQ, EU, USDA, GCC.

- Real-Time Updates — Inspection data, KPIs, and notifications.

- Full Audit Trails — ISO 9001 aligned, defensible in disputes.

- ERP Integration — Sync with supply chain systems.

Clients gain unmatched transparency, faster clearances, and arbitration-ready traceability with every shipment. See Certificate Sample → | Request Portal Access →

Fresh Produce Sorting & Quality Inspection (Apples)

Portal Features

- QR-secure certificates for every shipment.

- Interactive dashboards with trade KPIs.

- Archived inspection records, accessible globally.

Client Value

Faster clearance, real-time compliance visibility, and defensible documentation trusted by buyers, banks, and regulators. Request Access →

Case Studies & Applications

BQCIS provides practical inspection outcomes across agriculture and forestry supply chains. Each case study highlights how independent oversight prevents disputes, ensures compliance, and protects value for global clients.

- Sesame to EU — 100% clearance, no MRL failures.

- Chicken Paws to China — Zero CIQ rejections.

- Cocoa RA Program — +30% buyer compliance.

Explore more sector-specific examples in our Case Studies Library →

Bulk Grain Harvest & Storage Inspection

Case Study Highlights

Assurance Value

Case studies demonstrate measurable impact: reduced rejections, improved compliance, and enhanced buyer trust across global markets. Read More →

Core Agriculture Coverage

BQCIS provides end-to-end inspection and assurance for agricultural commodities — from pre-harvest audits to post-harvest storage and export verification. Our programs ensure crop integrity, regulatory compliance, and trade readiness.

Crops & Harvest Integrity

- Pre-harvest audits — soil, irrigation, pesticide use.

- Harvest monitoring and contamination prevention.

- Post-harvest storage hygiene and fumigation audits.

Seeds, Inputs & Agrochemicals

- Seed quality — germination, GMO, purity.

- Fertilizer compliance (EU 2019/1009 aligned).

- Agrochemical testing & traceability.

Soil, Water & Environmental Monitoring

- Soil fertility & heavy metal testing.

- Irrigation and potable water safety.

- Environmental impact audits — biodiversity & carbon.

Pest & Disease Management

- Quarantine inspections for invasive species.

- Integrated Pest Management (IPM) verification.

- Phytosanitary certification (IPPC aligned).

Grain Silo Storage & Preservation Inspection

Storage Tools

Assurance Value

Independent silo inspections safeguard grain quality, prevent losses, and ensure compliance with international trade standards. Read More →

Forestry & Timber Traceability

BQCIS provides end-to-end inspection and certification across forestry, timber, and agroforestry supply chains. From hydroponic greenhouse systems to traditional lumber, our methodologies ensure compliance with sustainability, traceability, and market-access regulations. Each audit is defensible under EUDR, FSC/PEFC, and international forestry protocols.

- Chain of custody verification — FSC & PEFC alignment.

- EUDR compliance — Deforestation-free sourcing checks.

- Illegal logging prevention — stump-to-mill audits.

- Paper, pulp & biomass certification — ISCC & RED II.

These measures assure buyers and regulators that timber, crops, and biomass products are sourced responsibly and in compliance with sustainability mandates. Read More →

Hydroponic Greenhouse Cultivation Inspection

Key Inspection Areas

Assurance Value

Hydroponic inspection supports market access and sustainability benchmarks, ensuring defensible results. Read More →

Agri-Food Safety & Perishables

BQCIS safeguards global food supply chains by ensuring that grains, produce, and perishables meet international quality and food safety benchmarks. Each inspection is carried out under ISO 22000, Codex Alimentarius, and aligned regional standards to ensure safe, market-ready commodities.

- Fresh Produce — Residue testing, microbiological safety, and cold-chain verification.

- Meat & Poultry — HACCP audits, antibiotic residue checks, and Halal/Kosher certification.

- Dairy & Cold Chain — Composition testing, hygiene audits, and refrigerated transport inspections.

- Export Compliance — SPS documentation and clearance support for EU, USDA, GCC, and CIQ markets.

These inspections prevent rejections at ports, protect consumer safety, and give exporters confidence in accessing international markets. Read More →

Corn (Maize) Bulk Quality & Grading Inspection

Grain Safety Checks

Assurance Value

Independent grading of corn ensures compliance with GAFTA, Codex, and USDA standards, reducing rejections and strengthening trade reliability. Read More →

Sustainability & Certification

BQCIS supports sustainable agriculture and forestry by ensuring global recognition of certification schemes. Our audits and verification programs help clients demonstrate compliance with environmental, social, and governance (ESG) benchmarks, while opening access to premium markets requiring sustainability credentials.

- Organic — EU 834/2007 & USDA NOP certification audits.

- Fair Trade & Rainforest Alliance — Ethical sourcing & labor standards.

- FSC / PEFC Forestry — Chain-of-custody traceability.

- ISCC EU / RED II — Sustainability criteria for biofuels & biomass.

- Reforestation Initiatives — Verified environmental restoration programs.

- Carbon Credit Verification — Agroforestry and biodiversity projects.

By aligning with recognized sustainability frameworks, BQCIS enables exporters and producers to prove compliance in ESG-sensitive markets. Read More →

Agricultural Storage Facility & Silo Compliance Audit

Assurance Value

Independent silo audits ensure food safety, reduce spoilage risks, and provide defensible evidence for GAFTA/FOSFA trade disputes. Read More →

Logistics & Cold Chain Oversight

BQCIS provides end-to-end oversight of logistics and cold chain systems to guarantee food safety, traceability, and compliance with global standards. From packaging and reefer monitoring to custody logging under Incoterms, we ensure agricultural goods arrive in optimal condition across borders.

- ISPM-15 Packaging Checks — Verification of wooden packaging treatment.

- Reefer Monitoring — IoT-enabled temperature & humidity tracking.

- Container Hygiene Audits — Inspection of containers for cleanliness & contamination.

- Custody & Seal Logs — End-to-end traceability under Incoterms.

These controls safeguard perishable goods, ensure defensible compliance at customs, and reduce cargo rejection risks. Read More →

Greenhouse Irrigation & Controlled Agriculture Systems

Oversight Focus

Assurance Value

Controlled agriculture audits ensure efficient production, reduce resource waste, and provide defensible certification for premium export markets. Read More →

Quinoa Grain Sampling & Quality Verification

BQCIS performs independent inspections of quinoa (Chenopodium quinoa) at every supply chain stage — from farm gate to export packaging. Our protocols guarantee defensible quality verification, ensuring that every shipment complies with Codex, ISO, and organic standards recognized worldwide.

- Grain Size & Uniformity — Verification of moisture, color, and density consistency.

- Purity & Cleanliness — Absence of stones, husks, and foreign matter.

- Organic/Fair-Trade Certification — Verification of claims under USDA/EU regulations.

- Export Labeling & Nutrition — Cross-checking packaging and nutritional labeling accuracy.

This process ensures international buyers receive quinoa that is clean, safe, and fully traceable for both conventional and organic markets. Read More →

Quinoa Grain Sampling & Quality Verification

Testing Focus

Assurance Value

Independent sampling ensures quinoa shipments meet buyer specifications, minimize rejection risks, and secure market access globally. Read More →

Key Areas of Agriculture & Forestry Assurance

Corn Grain Unloading & Bulk Verification

Grain Silo Storage & Logistics Inspection

Black Pepper Quality & Trade Inspection

Quinoa Export Sampling & Verification

Explore More Industries

Compliance & Standards References

- ISO Standards — Food safety, storage & logistics

- GAFTA Rules — Sampling & arbitration

- FOSFA Standards — Oils, fats & contract trade

- Codex Alimentarius — Food quality & safety

- BQCIS Digital Assurance Hub — QR-secured reports

- BQCIS Client Portal — Document archives

- Case Studies — Agricultural inspections