BQCIS — Industrial ManufacturingIndependent inspection and assurance across manufacturing supply chains |

The industrial manufacturing sector underpins global trade and infrastructure — from raw materials to finished components and complex machinery. Each production stage carries technical, regulatory, and commercial risks that demand impartial oversight. BQCIS provides third-party inspections, process audits, accredited laboratory testing, and certification services to ensure product quality, compliance, and operational efficiency.

Quick Navigation

- Why BQCIS

- QA/QC Program Design

- Supplier Qualification Audits

- Design & Document Review

- On-Site Supervision

- Non-Destructive Testing

- Welding Surveillance

- Coating & Surface Inspection

- Material Verification

- In-Plant QC Support

- FAT / SAT Witnessing

- Remote / Virtual Inspections

- Risk-Based Inspection

- Predictive Service-Life

- Materials & Component Testing

- Specialized Testing Programs

- Bulk & Cargo Inspection

- Weighing & Sampling Audits

- Accredited Laboratory Services

- Documentation & Traceability

- Calibration & Metrology

- Markets & Use Cases

- Client Outcomes

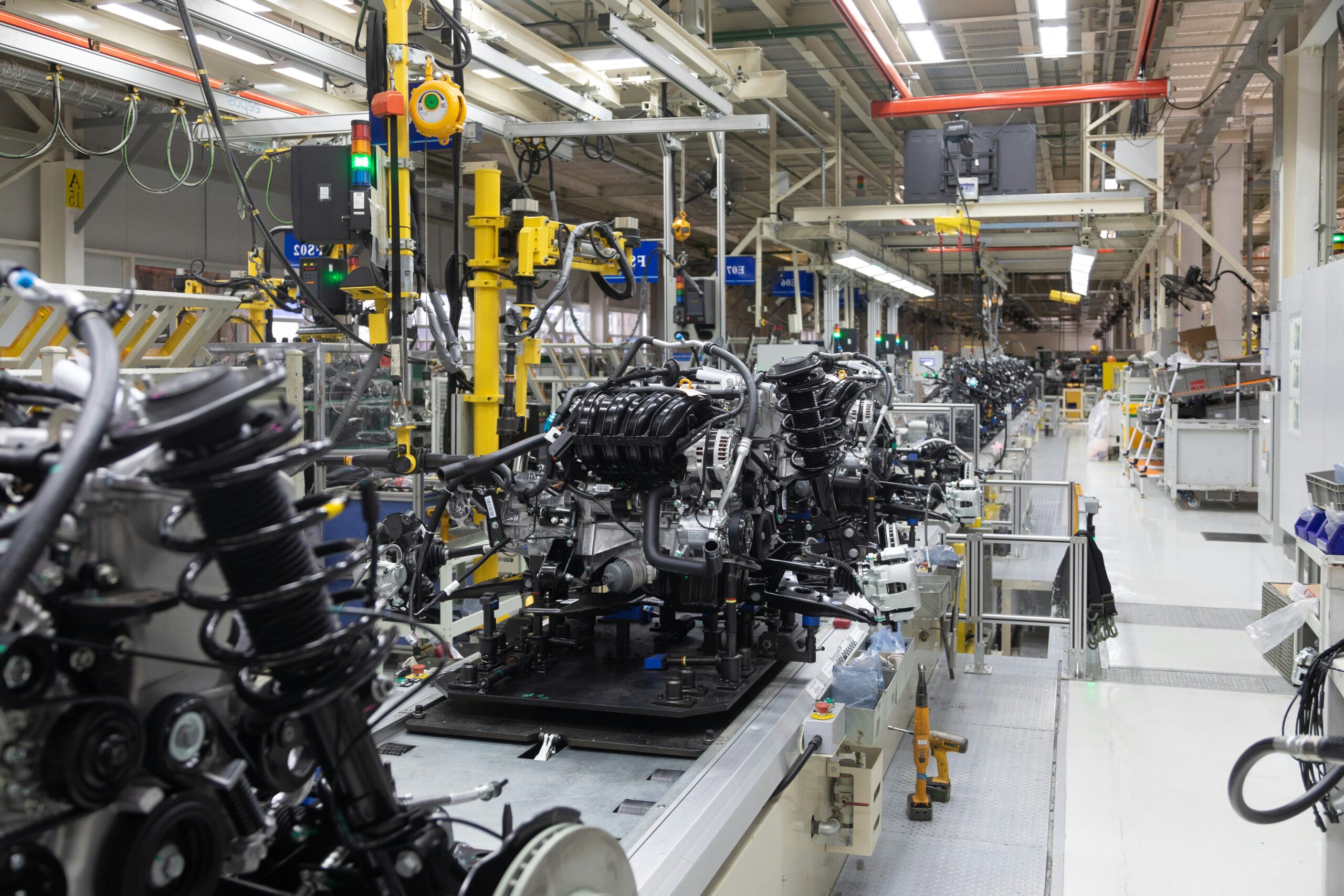

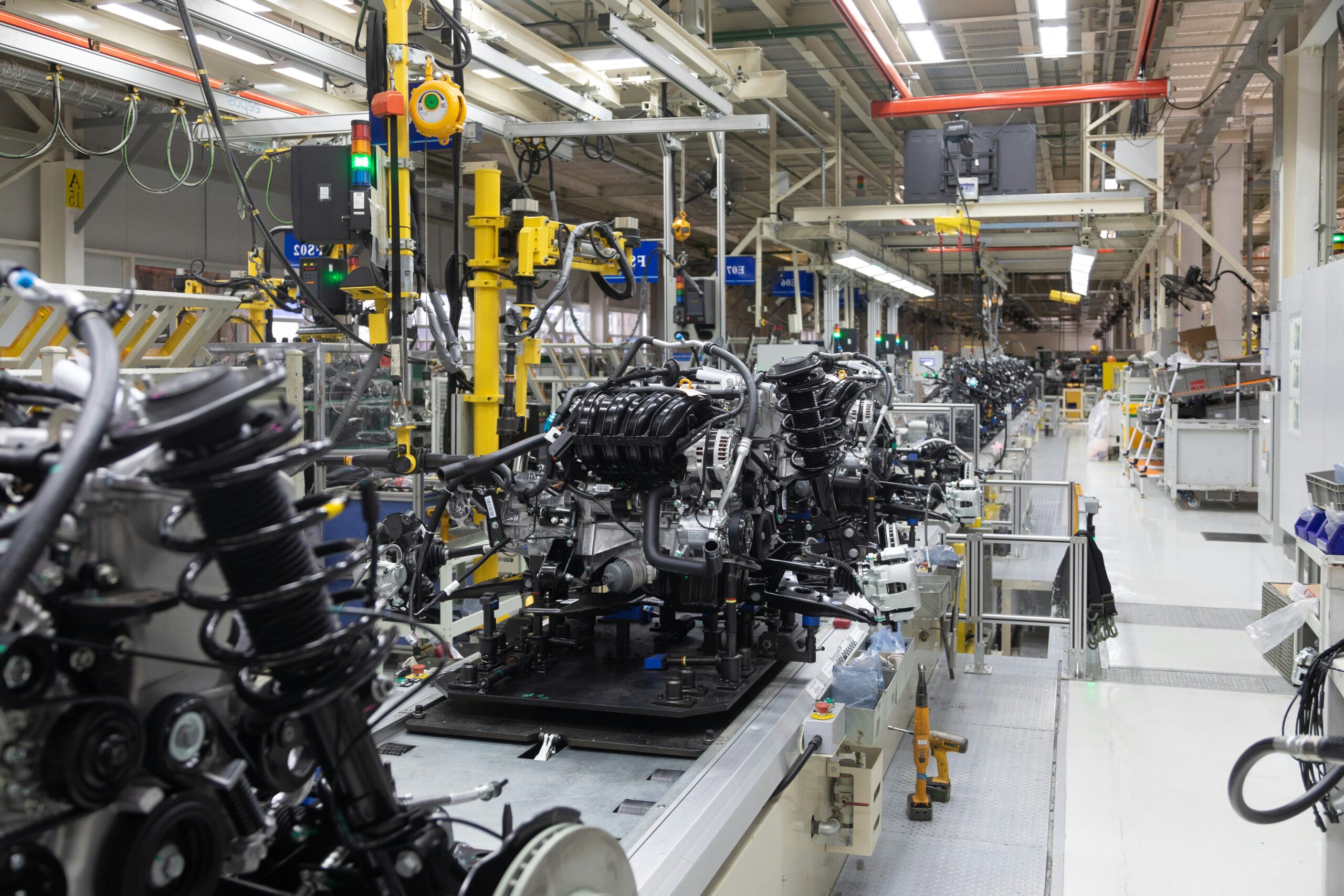

Inspecting equipment — Independent verification at factory floor

Inspection Checklist

- QA/QC Frameworks

- Supplier Audits

- Design Review

- On-Site Supervision

- Process Validation

- Equipment Calibration

- Product Performance Testing

- Packaging & Label Verification

- Final Pre-Shipment Inspection

- Regulatory Compliance Checks

- Material Traceability

- Workplace Safety Audits

- Environmental Impact Assessments

- Continuous Improvement Reviews

Why BQCIS in Manufacturing

Our impartial inspection services reduce risk, accelerate compliance, and ensure reliable delivery for clients across global supply chains. By combining international standards with sector-specific expertise, BQCIS provides trusted oversight at every production stage — from raw material sourcing to finished goods shipment.

- Independent verification – Neutral assurance of quality, safety, and compliance.

- Process efficiency – Early detection of deviations to minimize rework and downtime.

- Global alignment – Inspection and certification based on ISO, ASTM, and regional standards.

- Traceable reporting – QR-secured certificates, photo logs, and calibration references.

- End-to-end coverage – From supplier qualification to final delivery confirmation.

QA/QC Program Design

Structured quality assurance and control frameworks, sampling plans, and acceptance criteria ensure consistency across global operations. BQCIS develops and validates QA/QC programs that reduce variability, accelerate approvals, and meet contractual obligations. By applying ISO, ASTM, and sector-specific standards, our inspectors ensure all manufacturing checkpoints are documented, defensible, and globally recognized.

- Custom QA/QC frameworks aligned with international standards.

- Acceptance criteria validated against client and regulatory requirements.

- Risk-based sampling plans for large-scale production.

- Documented corrective and preventive action (CAPA) processes.

Manufacturing quality inspection — QA/QC oversight

QA/QC Checklist

Consistency & Assurance

QA/QC program design ensures manufacturing outcomes are consistent, defensible, and globally compliant. Read More →

Supplier Qualification Audits

Independent evaluation of supplier facilities, management systems, and process stability to reduce critical supply chain risks. BQCIS ensures suppliers meet international standards before being approved into your global supply chain. Our audits identify hidden weaknesses, mitigate sourcing disruptions, and support responsible procurement.

- Facility audits covering production, safety, and management systems.

- Validation of process stability and capacity to meet demand.

- Traceability and quality history verification.

- Alignment with ISO 9001 and sector-specific standards.

Onsite inspection — Supplier audit verification

Supplier Audit Checklist

Procurement Assurance

Supplier qualification audits reduce sourcing risk and strengthen global supply chain resilience. Read More →

Design & Document Review

Verification of engineering drawings, welding procedures, and technical specifications to confirm conformity before production begins. BQCIS ensures that blueprints, WPS/PQR, and process flows are validated by impartial inspectors before manufacturing starts. This reduces costly errors, delays, and rework during production.

- Review of technical drawings and schematics.

- Welding procedure and welder qualification validation.

- Conformance of raw material specs with project requirements.

- Independent third-party approval for major projects.

Onsite inspection — Document & design validation

Design Review Checklist

Project Assurance

Independent document reviews prevent costly delays and confirm project conformity. Read More →

On-Site Supervision & Witnessing

Direct oversight of manufacturing, welding, assembly, FAT/SAT, and construction to guarantee alignment with industry standards. BQCIS inspectors act as impartial witnesses to confirm every critical step is performed according to contract and compliance requirements. Our supervision reduces risks of rework, defects, and disputes.

- Welding, assembly, and machining supervision.

- Factory and Site Acceptance Tests (FAT/SAT) witnessed.

- Construction oversight with photographic documentation.

- End-to-end chain-of-custody maintained for all deliverables.

Onsite inspection — Supervision at loading port

Supervision Checklist

Risk Reduction

On-site supervision reduces disputes, prevents defects, and ensures compliance with international standards. Read More →

Non-Destructive Testing (NDT)

Ultrasonic, radiographic, magnetic particle, penetrant, leak detection, hydrostatic, and vacuum testing validate structural integrity without causing damage. BQCIS deploys accredited inspectors and modern NDT equipment to confirm fitness-for-service of fabricated parts, welded joints, and critical assets. This ensures safety, reliability, and extended lifecycle performance across global industries.

- Ultrasonic, X-ray, and radiographic testing.

- Magnetic particle and penetrant checks.

- Vacuum, hydrostatic, and leak detection methods.

- Defensible reporting with QA/QC traceability.

NDT validation — Independent non-destructive testing

NDT Checklist

Structural Reliability

NDT ensures hidden flaws are detected before costly failures. Read More →

Welding Surveillance

Continuous monitoring of welding fit-up, heat input, consumables, and welder qualifications to meet approved WPS/PQR standards. BQCIS welding inspectors ensure welds meet mechanical and metallurgical requirements across industries from pipelines to pressure vessels.

- Fit-up and alignment checks for critical welds.

- Consumable batch and traceability control.

- Heat input monitoring and interpass validation.

- WPS/PQR compliance audits.

Onsite inspection — Welding surveillance

Welding Checklist

Structural Confidence

Welding surveillance ensures joints meet strength, safety, and compliance standards. Read More →

Coating & Surface Inspection

Evaluation of protective coatings for thickness, adhesion, porosity, and durability in service environments. BQCIS inspectors verify surface preparation, coating application, and curing conditions to ensure long-term asset protection.

- Surface preparation validation (blast profile, cleanliness).

- Coating thickness and adhesion testing.

- Porosity and holiday detection with calibrated tools.

- Durability checks aligned with ISO/ASTM standards.

Loading inspection — Coating validation

Coating Checklist

Long-Term Protection

Coating inspections safeguard industrial assets against corrosion and premature failure. Read More →

Material Verification & Sampling

Independent collection and validation of raw materials and components through statistical sampling and traceable chain-of-custody. BQCIS inspectors verify compliance of steel, alloys, polymers, and composites with procurement specifications and international standards. This prevents substandard inputs from entering production lines, reducing rework, warranty claims, and costly disputes.

- Sampling of incoming raw materials and parts.

- Material verification against certificates of analysis.

- Traceable chain-of-custody protocols.

- Alignment with ASTM, ISO, and EN requirements.

Onsite report — Material verification & sampling

Verification Checklist

Defensible Results

Material verification ensures arbitration-ready documentation for compliance and trade defensibility. Read More →

Embedded In-Plant QC Support

Deployment of BQCIS technicians within production facilities provides real-time oversight and immediate corrective action. In-plant QC reduces downtime by identifying non-conformities early, supporting manufacturers in maintaining high standards of safety and quality. Embedded teams ensure seamless integration with client operations, aligning factory output with international expectations.

- Onsite inspectors embedded directly into client facilities.

- Real-time detection of non-conforming products.

- Corrective actions implemented during production flow.

- Improved first-pass yield and reduced scrap.

Loading supervision — Embedded QC support

QC Support Checklist

Operational Efficiency

Embedded QC reduces waste, accelerates approvals, and safeguards global client operations. Read More →

FAT / SAT Witnessing

Independent witnessing of Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT) confirms that manufactured equipment performs as specified. BQCIS inspectors validate safety, dimensional accuracy, and compliance before equipment is shipped or commissioned. Our impartial oversight protects both buyers and suppliers by ensuring contractual conformity and eliminating costly rework.

- Validation of design requirements during FAT.

- Verification of safety interlocks, control systems, and calibration.

- SAT oversight ensures proper installation and functionality.

- Defensible reports accepted by regulators and financiers.

Quality testing — FAT & SAT witnessing

FAT / SAT Checklist

Reliable Deployment

Independent FAT/SAT oversight ensures safe, reliable deployment of industrial systems. Read More →

Remote / Virtual Inspections

BQCIS provides live video-based inspections where on-site presence is not possible. Virtual inspections deliver cost-effective, real-time oversight for clients across the globe. Using AR-enabled headsets, mobile cameras, and secure data platforms, we maintain the same rigor as physical inspections while reducing travel and delays.

- Remote witnessing of tests, assembly, and inspections.

- Secure platforms for video recording and audit trails.

- Augmented reality tools for interactive validation.

- Fast deployment across multiple international sites.

Remote inspection — Video-based oversight

Remote Inspection Checklist

Cost & Time Savings

Remote inspections cut travel delays, reduce costs, and maintain compliance. Read More →

Risk-Based Inspection (RBI)

BQCIS applies risk-based inspection methodologies to prioritize resources on critical equipment and structures. RBI identifies components with the highest probability and consequence of failure, ensuring inspection frequency is optimized for safety, compliance, and lifecycle cost management. This data-driven approach prevents catastrophic failures and extends asset longevity.

- Criticality assessment of industrial components.

- Inspection intervals determined by risk level.

- Focus on pressure vessels, civil structures, and rotating equipment.

- Integration with asset management and predictive tools.

RBI approach — Critical asset inspection

RBI Checklist

Critical Assurance

RBI ensures safety and compliance while focusing inspections on the most critical assets. Read More →

Predictive Service-Life Estimation

BQCIS applies advanced modeling techniques to estimate the expected lifespan of industrial assets and components. Predictive models factor in stress conditions, load cycles, corrosion environments, and historical performance data. This approach helps operators plan preventive maintenance, budget for replacements, and extend the safe working life of their equipment.

- Finite element analysis (FEA) of stress and fatigue.

- Corrosion modeling under varying environments.

- Maintenance forecasting & lifecycle costing.

- Failure mode & effects analysis (FMEA).

Predictive modeling — Estimating asset service life

Service-Life Checklist

Lifecycle Value

Predictive tools minimize downtime and ensure asset integrity through accurate lifecycle forecasting. Read More →

Materials & Component Testing

Independent testing of materials and components provides full assurance of structural integrity. BQCIS laboratories and field teams perform a broad spectrum of tests including mechanical, metallurgical, chemical, and corrosion analyses. Our results are reproducible, defensible, and internationally recognized for trade and compliance.

- Mechanical testing: tensile, impact, hardness.

- Metallography and microstructure analysis.

- Chemical analysis: OES, ICP, XRF.

- Corrosion & accelerated aging studies.

- Failure investigations for root cause analysis.

Materials & component testing — Assuring quality

Testing Checklist

Defensible Results

Testing ensures materials meet global standards and withstand real-world conditions. Read More →

Specialized Testing Programs

BQCIS develops tailored inspection and testing programs for industry-specific needs. These programs address specialized areas such as renewable energy systems, packaging, labeling, and regulatory certifications. Our approach ensures sector requirements are fully met and globally defensible.

- Photovoltaic plant inspections and certification.

- Safety labeling & compliance verification.

- Packaging audits for transport and storage.

- Sector-specific regulatory compliance audits.

Specialized testing — Tailored inspections

Testing Programs Checklist

Sector Readiness

Custom testing ensures products and systems comply with specialized industry standards. Read More →

Bulk & Cargo Inspection

Independent supervision of bulk and containerized shipments ensures that products meet quality, quantity, and cleanliness requirements. BQCIS inspectors perform tally surveys, moisture checks, and contamination prevention audits to guarantee trade defensibility. Our evidence-based inspections are aligned with GAFTA/FOSFA standards and are arbitration-ready.

- Container inspection for cleanliness and suitability.

- Sampling & sealing of cargo under custody protocols.

- Moisture checks for grains, powders, and bulk solids.

- Tally & weight reconciliation at loading/discharge.

Bulk shipment supervision — Cargo verification

Cargo Checklist

Defensible Logistics

Independent verification reduces disputes and accelerates settlement. Read More →

Weighing & Sampling Audits

Accuracy in weighing and sampling is critical to fair trade settlements. BQCIS performs audits of weighing equipment, calibration checks, and sampling methods to ensure defensible results. Our auditors verify balances, scales, conveyors, and sampling systems against ISO and trade protocols.

- Calibration checks of scales & weighbridges.

- Sampling system performance validation.

- Cross-verification with umpire methods.

- Documentation aligned with GAFTA/FOSFA frameworks.

Weighing & sampling audits — Ensuring accuracy

Audit Checklist

Fair Settlement

Reliable weighing and sampling protect both buyers and sellers from hidden losses. Read More →

Accredited Laboratory Services

BQCIS laboratories are ISO/IEC accredited and provide a full range of testing for metals, polymers, chemicals, and agricultural products. Our labs apply validated methods, proficiency-tested instruments, and strict QA/QC protocols. Reports are defensible, internationally recognized, and suitable for arbitration.

- Chemical & metallurgical analysis (OES, ICP, XRF).

- Physical property testing (hardness, density, moisture).

- Environmental & EHS testing (emissions, water quality).

- Agricultural & food-grade quality tests.

Laboratory services — ISO/IEC accredited testing

Lab Services Checklist

Defensible Reports

Accredited laboratory services ensure reports are recognized globally for trade, arbitration, and compliance. Read More →

Documentation & Traceability

BQCIS delivers a complete “Evidence Pack” to support defensible verification in industrial manufacturing. Every inspection is supported by dimensional reports, calibration records, NDT dossiers, timestamps, and photographic logs. These traceable documents are QR-secured and fully auditable for regulatory, contractual, and commercial settlement purposes.

- Dimensional checks and GD&T compliance reports.

- Complete NDT dossiers with reference standards.

- Photo & video logs of inspection and testing stages.

- Calibration certificates linked to traceable standards.

- QR-secured digital Evidence Packs for banks and auditors.

Traceable inspection documentation & Evidence Pack

Traceability Checklist

Why Traceability Matters

Traceable, QR-secured documentation ensures contract defensibility, reduces disputes, and accelerates shipment release. Read More →

Calibration & Metrology

Reliable measurement is the foundation of industrial quality assurance. BQCIS verifies gauges, instruments, and dimensional measurement systems under ISO/IEC standards. Our services cover calibration traceability, coordinate measuring machine (CMM) verification, and reproducibility studies.

- Gauge verification and instrument calibration.

- CMM dimensional checks against GD&T standards.

- Gage R&R and reproducibility studies for consistency.

- Calibration traceability to ISO/IEC 17025 standards.

- Comprehensive calibration records included in Evidence Packs.

Gauge verification & dimensional metrology

Calibration Checklist

Metrology Confidence

Defensible calibration and dimensional verification underpin trust in global manufacturing and reduce costly rework. Read More →

Markets & Use Cases

BQCIS supports a broad spectrum of industrial manufacturing markets by delivering consistent quality oversight, safety validation, and compliance checks across production lines and end-use components. Our inspectors and auditors work globally to ensure that manufacturing processes, testing protocols, and certifications align with international standards, mitigating risks and reducing costs.

- Welded structures, pressure vessels, and pipelines.

- Machined parts, castings, and precision components.

- Electrical panels, transformers, and switchgear assemblies.

- Packaging lines and food-grade equipment.

- Heavy equipment, automotive, aerospace, and electronics.

- Building materials, prefabricated structures, and civil products.

- Oil & Gas downstream equipment and energy transition assets.

Production inspection across multiple markets

Markets Checklist

Why It Matters

Market-focused inspection ensures sector-specific compliance, accelerates approvals, and improves trust across supply chains. Read More →

Client Outcomes

Every BQCIS program delivers measurable outcomes for clients by strengthening compliance, building trust, and protecting value. Our oversight reduces costly production errors, minimizes disputes, and provides defensible evidence packs for global regulators and financiers. By embedding traceability and real-time checks into manufacturing processes, BQCIS ensures clients meet contractual, technical, and ESG requirements.

- Reduced defects and warranty claims through proactive QA/QC.

- Accelerated shipment approvals with pre-verified inspection results.

- Audit-ready documentation packages for international regulators.

- Stronger market credibility through transparent compliance.

- Consistent global assurance across suppliers and facilities.

Client outcomes — Reliable inspection success

Outcome Checklist

Stronger Market Credibility

Clear evidence and global recognition reduce disputes and improve commercial trust. Read More →

Key Areas of Industrial Manufacturing Assurance

Inspection of Industrial Equipment

Warehouse Quality Inspection

Quality Test Verification

Compliance & Documentation

Explore More Industries

Compliance & Standards References

- ISO 9001 — Quality Management Systems

- ASTM — Testing, calibration & verification protocols

- IEC Standards — Electrical & electronic equipment

- ISO/IEC 17025 — Laboratory Competence & Calibration

- BQCIS Digital Assurance Hub — Client dashboards & QR-secured reports

- BQCIS Client Portal — Report archives & KPIs

- Case Studies — Practical inspection examples