Verifying Material Integrity for Flight Safety

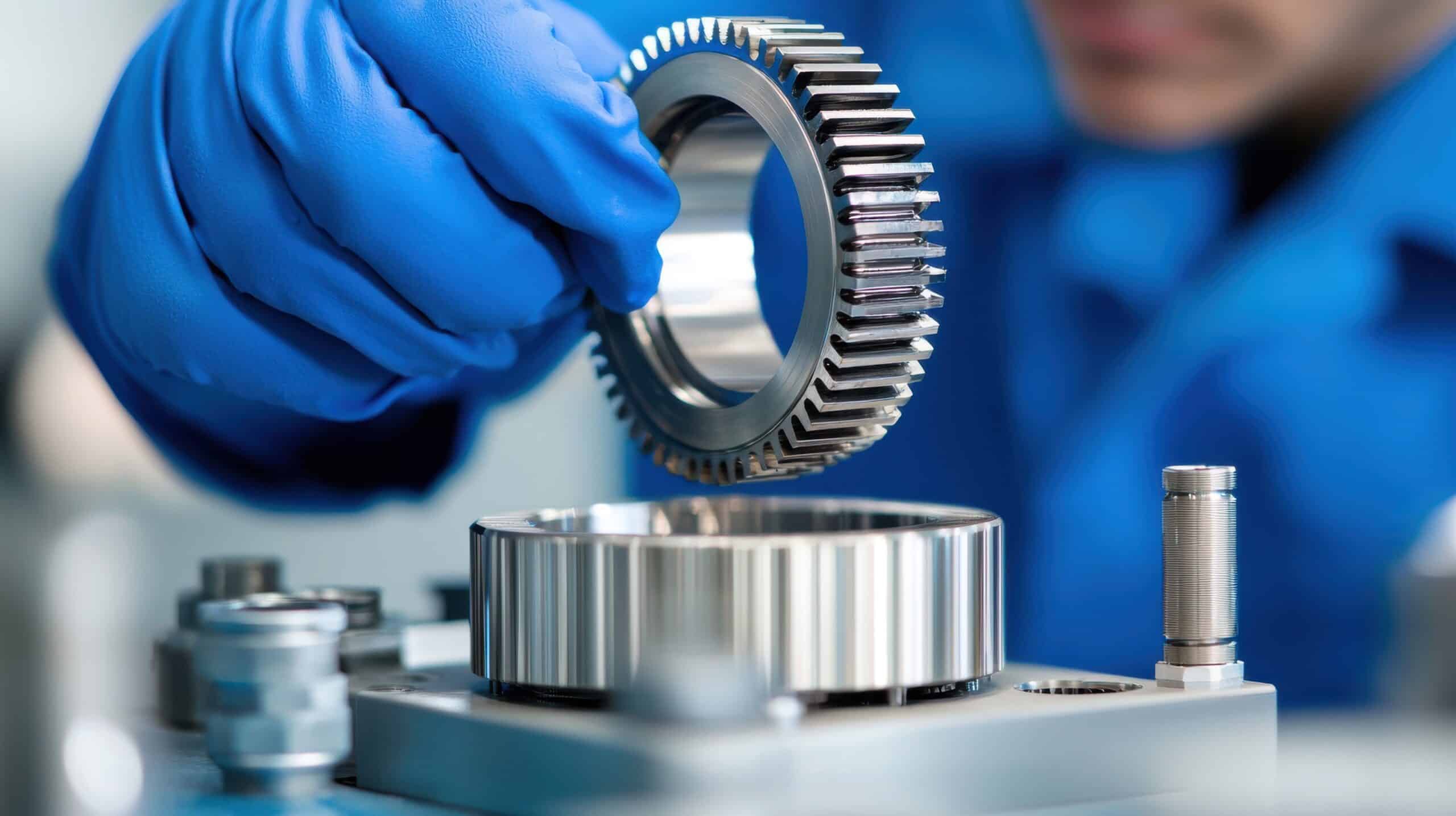

Materials used in aircraft, spacecraft, and defense systems must meet the most stringent safety and performance standards. Aerospace materials testing ensures the integrity and reliability of these materials through each production stage — from raw metal inspection to post-manufacturing qualification.

BQCIS operates Nadcap-compliant laboratories for destructive and non-destructive testing of titanium, aluminum, high-strength steels, and advanced composites. We validate compliance with AMS, ASTM, and ISO specifications.

Our experts perform tensile, fatigue, corrosion, and fracture testing to identify critical failure modes such as fatigue cracking and stress corrosion. Verified test data ensures regulatory approval and long-term safety of all aircraft and spacecraft components.

Key Materials Testing Activities

Key Benefits of Aerospace Material Testing

Enhanced Flight Safety

Ensures every critical component meets design stress and fatigue criteria, preventing structural failures in service.

Regulatory & OEM Compliance

Complies with AMS, ASTM, and Nadcap standards for full traceability and customer specification conformity.

Optimized Material Performance

Advanced mechanical and corrosion data help engineers select materials with superior lifecycle efficiency.

Independent Quality Assurance

Third-party verification by BQCIS demonstrates unbiased validation to regulators and aerospace primes.

Success Story

Fatigue Testing Validates Engine Component Lifespan

A turbine blade manufacturer needed proof that a new lightweight alloy met fatigue life and stress endurance requirements before OEM qualification.

BQCIS executed a comprehensive Low-Cycle Fatigue (LCF) program simulating full operational loading and thermal cycles in compliance with AMS protocols.

The new alloy achieved all required cycles-to-failure, and BQCIS issued certified reports supporting OEM approval and safe integration into production. This accelerated the customer’s qualification timeline while maintaining full safety assurance.