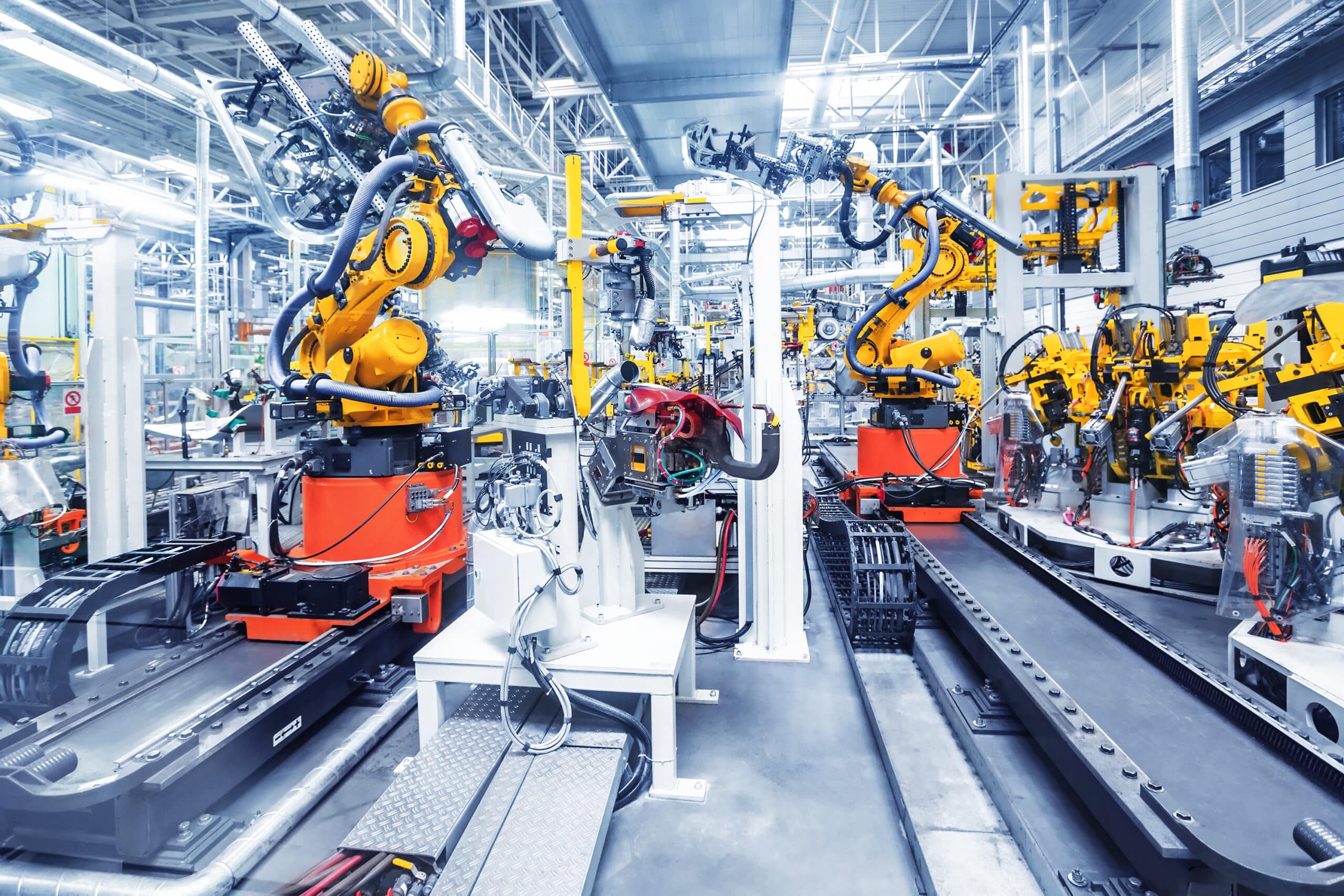

Building Quality into Every Manufacturing Step

Production Quality Assurance (PQA) is the proactive approach to preventing defects and ensuring that manufacturing processes consistently yield conforming products. Rather than relying solely on final inspection, PQA ensures control systems and process capability directly on the line.

BQCIS provides specialized PQA services including process audits, Statistical Process Control (SPC) validation, inline inspection, end-of-line verification, and ISO 9001 process compliance. We ensure stability, capability, and sustained quality output.

Our objective: reduce variability, eliminate defects, protect profitability, and maintain the highest level of production reliability.

Key Quality Assurance Activities

Process Audits & Statistical Process Control (SPC) Validation

Our auditors assess manufacturing process stability and capability, verifying calibration of inline monitoring equipment and confirming compliance with SOPs. We validate your SPC systems—ensuring control charts are correctly applied, interpreted, and acted upon. This prevents drift, minimizes variability, and eliminates the root causes of major defects.

In-Line Inspection & Product Conformity Checks

Our inspectors perform systematic checks on semi-finished and finished goods, verifying conformity against dimensional, functional, and visual specifications. This includes First Article Inspection (FAI) and validation of end-of-line testing effectiveness. Independent oversight ensures stable, repeatable production quality.

Key Benefits of Our Training

Build Internal Competency

Equip your manufacturing teams with the knowledge to maintain and scale quality systems effectively.

Ensure System Effectiveness

Strengthen production controls, risk management, and root-cause prevention mechanisms.

Drive Continual Improvement

Identify inefficiencies, optimize process flow, and eliminate repetitive non-conformities.

Achieve & Maintain Certification

Ensure readiness for ISO 9001 audits and customer-specific production capability assessments.

Success Story

SPC Validation Eliminates Recurring Dimensional Defects

A high-volume auto manufacturer suffered recurring dimensional defects their internal controls couldn’t detect early enough.

BQCIS audited SPC charts, measurement systems, and operator reaction protocols. Root-cause analysis revealed misinterpretation trends and late corrective actions on the night shift.

By retraining staff and automating SPC data analysis, the manufacturer achieved a Six Sigma level of stability and eliminated the recurring defects entirely—saving millions in scrap and warranty cost.