Assuring the Integrity and Safety of High-Voltage Systems

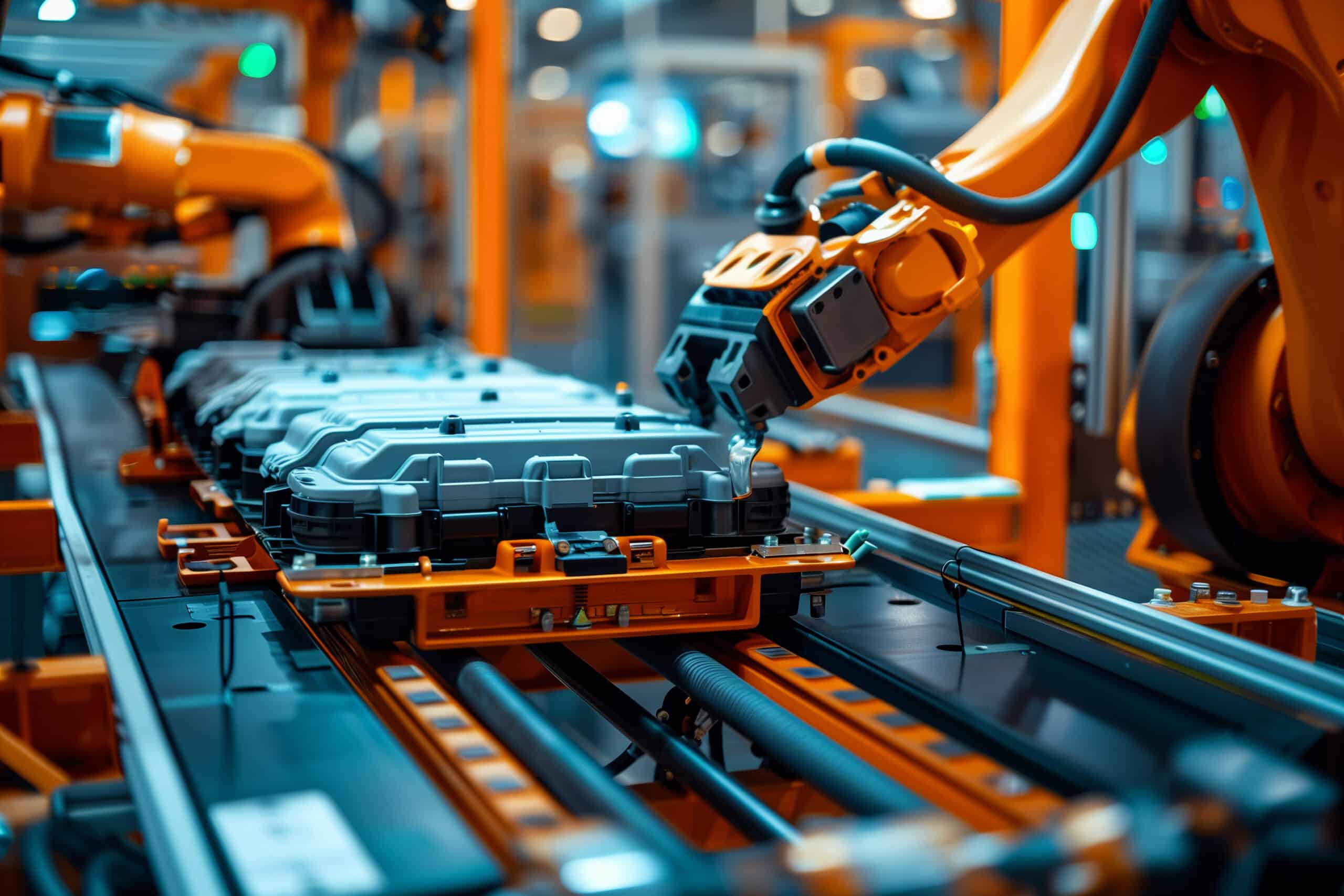

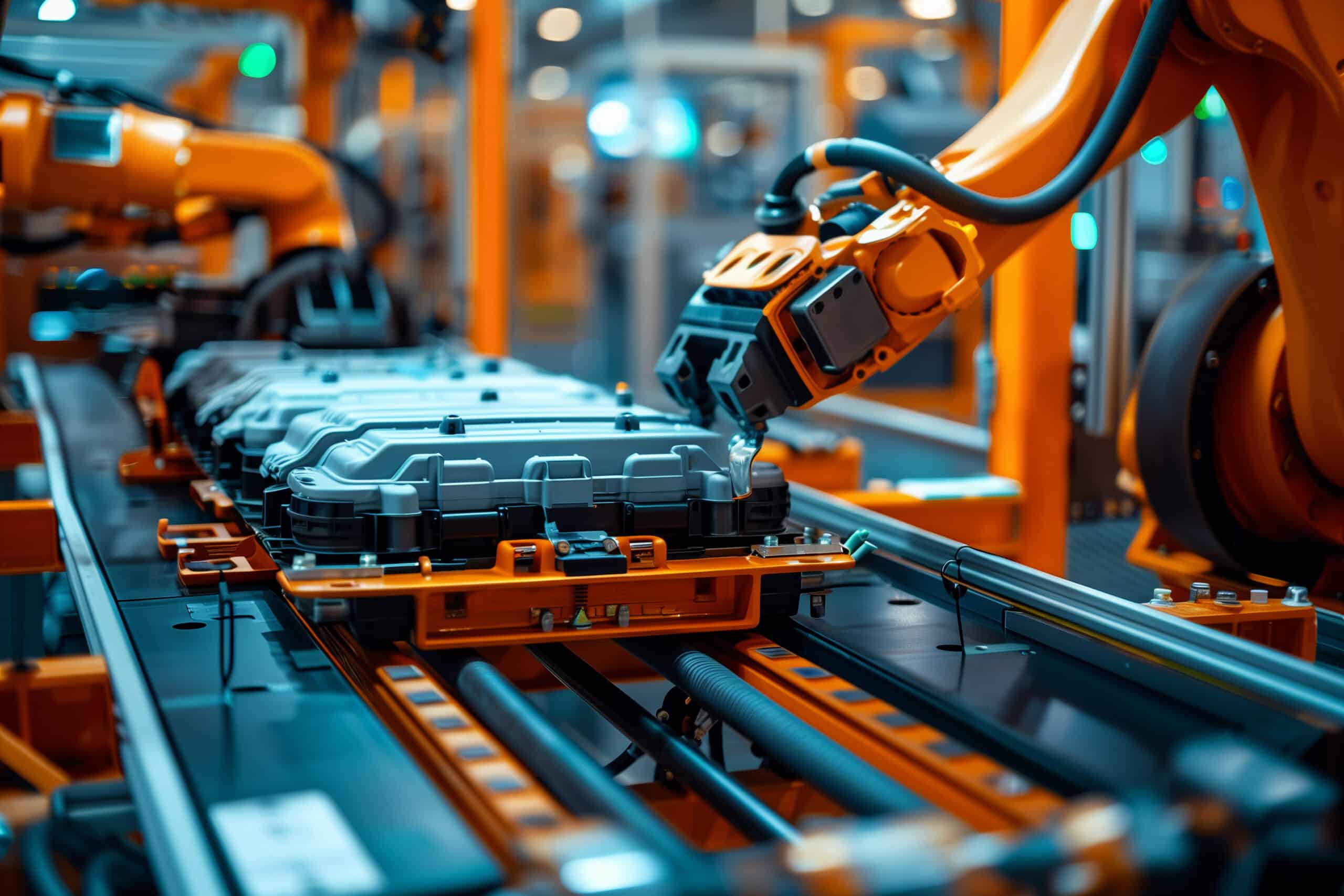

The safety of electric vehicles (EVs) hinges on the reliability of their battery packs. Given the high energy density of modern lithium-ion batteries, testing for failure modes—including thermal runaway, internal short circuits, and mechanical breach—is the most critical requirement for manufacturers.

BQCIS provides comprehensive testing and certification services covering battery cells, modules, and full packs. We execute rigorous abuse testing, validating battery system resilience against UN 38.3, IEC 62619, GB/T, and OEM-specific standards.

Our services cover electrical safety (insulation, high-voltage checks), mechanical durability (shock/vibration), and environmental performance. We provide verified, independent data to ensure global compliance, prevent fire risks, and support market access.

Key Testing and Certification Activities

Abuse, Thermal, and Electrical Safety Testing

We conduct critical abuse testing to assess battery resilience under crush, puncture, heat exposure, and electrical faults. Thermal runaway propagation resistance is validated at cell, module, and pack level. High-voltage isolation, insulation resistance, and overcharge protection are tested per UL 2580 and IEC 62619 to ensure safety and compliance for global EV markets.

Mechanical Durability and Transport Certification (UN 38.3)

We validate vibration, shock, drop, and environmental stresses to ensure safe operation and transport. All required UN 38.3 tests—including T.1 to T.8—are performed to certify batteries for global air, road, and sea shipment. This mandatory certification ensures safe logistics and international compliance for battery shipments.

Key Benefits of Our Training

Build Internal Competency

Equip your team with a technical understanding of EV battery risk factors, test methods, and compliance pathways.

Ensure System Effectiveness

Improve engineering control, safety monitoring, and prevention systems across battery development and production.

Drive Continual Improvement

Empowered teams can identify design flaws, improve thermal management, and optimize battery safety features.

Achieve & Maintain Certification

Training ensures readiness for global certification audits including UN 38.3, IEC, UL, and GB/T conformity requirements.

Success Story

UN 38.3 Testing Secures Global Export of EV Battery Cells

A battery manufacturer could not ship new lithium-ion cells internationally due to missing UN 38.3 certification, causing a major supply chain delay.

BQCIS executed the full UN 38.3 test series including thermal, vibration, shock, short-circuit, and crush testing using certified equipment and accredited labs.

The cells passed all 8 required tests. BQCIS issued the official UN 38.3 report, enabling global shipment and unlocking OEM supply contracts.