Verifying Material Performance and Protection

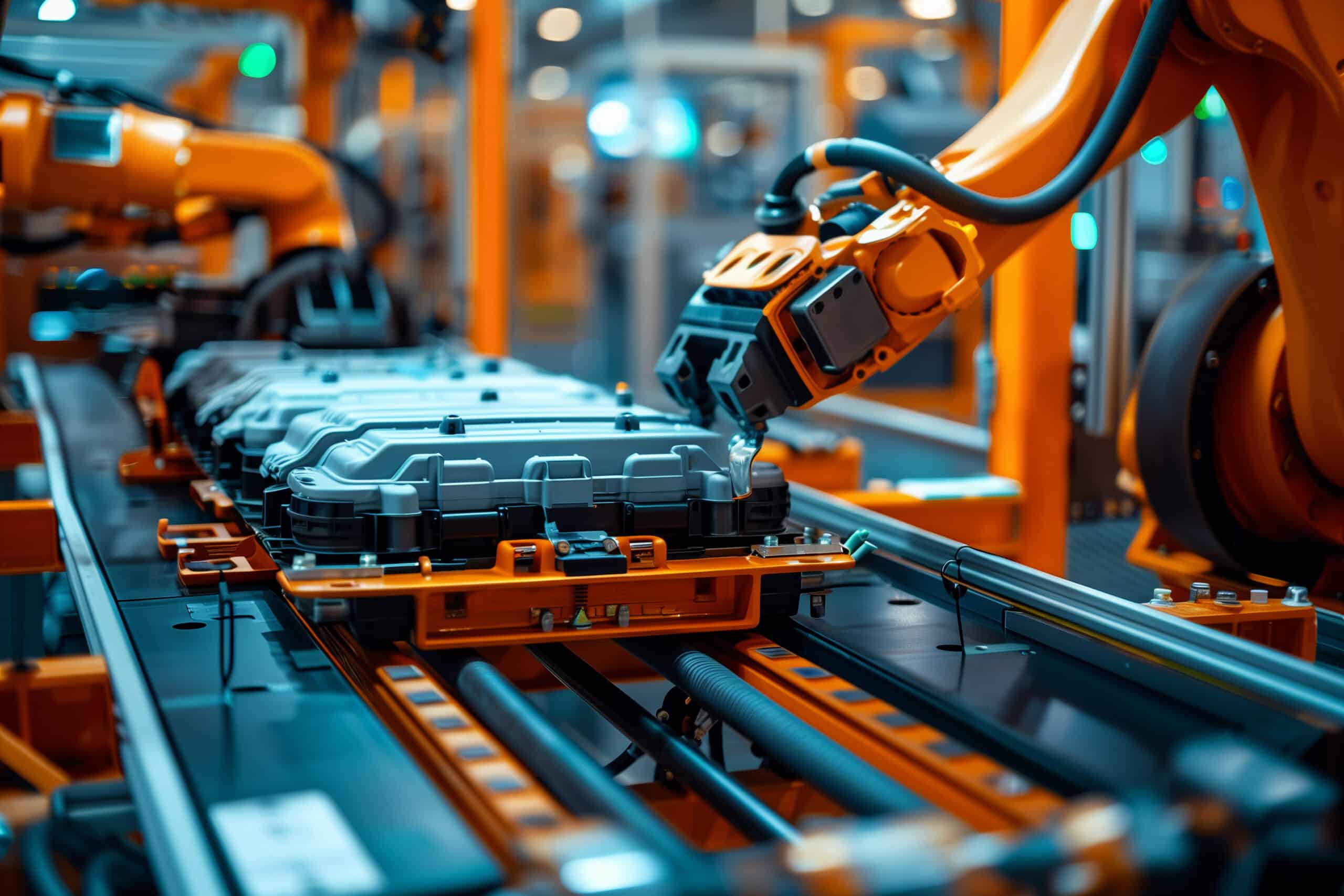

The safety and reliability of industrial components depend on material integrity and coating durability. BQCIS provides full destructive and non-destructive testing to validate both.

Our accredited labs test metals, alloys, composites, and coatings. We verify strength (tensile, impact, hardness), composition (PMI, OES, XRF), and surface protection systems.

We also conduct accelerated corrosion simulations, adhesion testing, coating thickness checks, and porosity verification to ensure long-term reliability and compliance.

Key Laboratory Testing Activities

Destructive Mechanical & Chemical Analysis

Tensile, hardness, impact, and fatigue testing to verify mechanical properties, combined with chemical analysis (PMI, OES, XRF) to confirm alloy grade and compliance with specifications.

Coating Integrity & Corrosion Testing

Salt spray, humidity, and CASS tests validate corrosion resistance. We measure coating thickness (DFT), adhesion (pull-off, cross-hatch), and porosity to confirm long-term protection.

Key Benefits of Our Training

Build Internal Competency

Develop strong technical understanding of material and coating performance requirements.

Ensure System Effectiveness

Strengthen internal quality control and laboratory interpretation of test results.

Drive Continual Improvement

Identify risks early and implement corrective actions to prevent field failures.

Achieve & Maintain Certification

Ensure compliance with global material and coating standards for critical industries.

Success Story

Material Testing Prevents Catastrophic Component Failure

A client experienced a catastrophic failure of a structural component suspected to be caused by incorrect steel grade.

BQCIS conducted full metallurgical and mechanical analysis, performing PMI, tensile, hardness, and chemical testing.

The analysis confirmed the supplier substituted the specified alloy with inferior steel, preventing further failures and enabling corrective action across their supply chain.