Assuring Reliability and Safety in Rail Operations

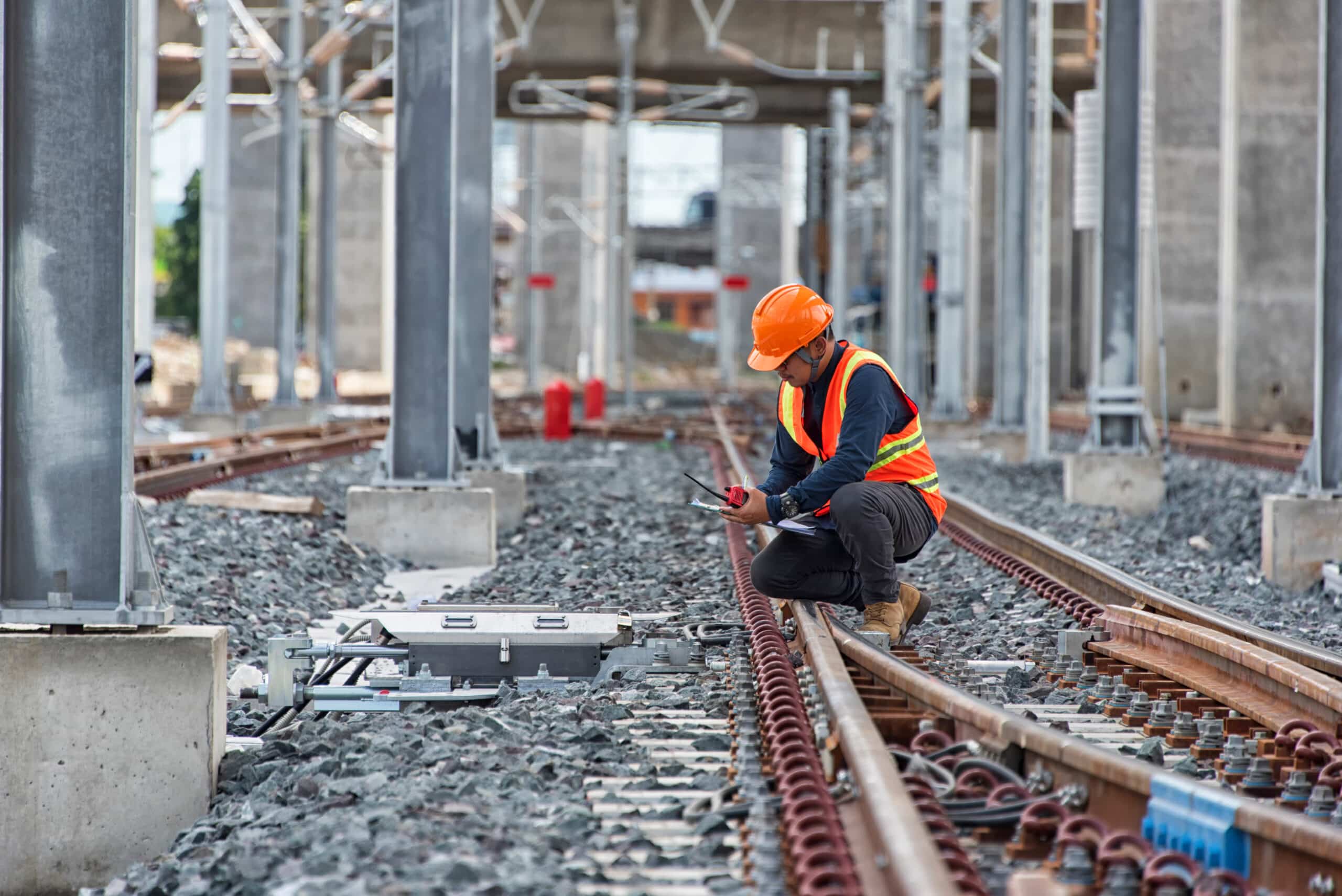

The railway and metro sectors are defined by high demands for safety, reliability, and long-term asset integrity. Components, tracks, bridges, and rolling stock are subjected to immense mechanical stress and fatigue loading over decades of service. Ensuring their continued structural soundness is critical for preventing derailments, minimizing downtime, and protecting passenger safety.

BQCIS provides comprehensive independent inspection and testing services tailored to rail standards (EN, AREMA, FRA). Our expertise covers both the fixed infrastructure and the rolling stock assets. We utilize specialized Non-Destructive Testing (NDT) techniques to detect rail flaws, axle cracks, and weld defects in bogies and car bodies.

Our services include surveillance during the manufacturing of new rolling stock, periodic in-service inspection of tracks and bridges, and verification of maintenance and repair (M&R) quality. By providing certified inspection and verification, we help rail operators meet rigorous regulatory requirements and maximize the safe lifespan of their infrastructure.

Key Integrity Activities

Key Benefits of Rail Assurance

Enhanced Passenger Safety

Early detection of rail and axle defects minimizes accident risk and guarantees operational safety across the network.

Reduced Maintenance Costs

Timely inspections and predictive maintenance strategies lower long-term repair expenses and equipment downtime.

Regulatory Compliance

Certified reports align with EN, AREMA, and FRA regulations, supporting smooth audits and continued operational approval.

Extended Asset Lifespan

Periodic integrity verification and defect tracking maximize the service life of critical track and rolling-stock assets.

Success Story

Axle Inspection Prevents Rolling Stock Derailment Risk

A regional metro system initiated a fleet-wide axle inspection after a derailment incident was suspected to stem from fatigue damage in wheelsets.

BQCIS deployed mobile NDT units using ultrasonic and magnetic particle testing (UT/MT) per EN 13260, ensuring in-situ coverage without service disruption.

Several high-stress axles exhibiting sub-surface cracks were replaced proactively, preventing failure, extending fleet life, and safeguarding passengers and operations.